The Serra Sul iron ore mine located in the Canaã dos Carajás municipality, Para, Brazil is being expanded to increase the annual production capacity by 20 million tonnes (Mt) to 120Mt.

Owned and operated by Vale, the Serra Sul mine has been producing since December 2016. The Serra Sul integrated operation comprises the S11C and the S11D iron ore deposits that form part Vale’s Northern System mining complex in Carajás.

The project was developed with an estimated investment of £10.8bn ($14.3bn), of which approximately £4.8bn ($6.4bn) accounted for the construction of the mine and the plant.

Although the Serra Sul mine produced 73.4Mt of iron ore in 2019, its design production capacity currently stands at 90Mtpa.

Vale announced an expansion plan to increase Serra Sul’s production capacity by 10Mtpa to 100Mtpa by 2022, in December 2018.

Further in August 2020, the company announced a £1.1bn ($1.5bn) expansion project called Serra Sul 120 to increase the mine’s production capacity by 20Mtpa to 120Mtpa by 2024.

The Serra Sul 120 project

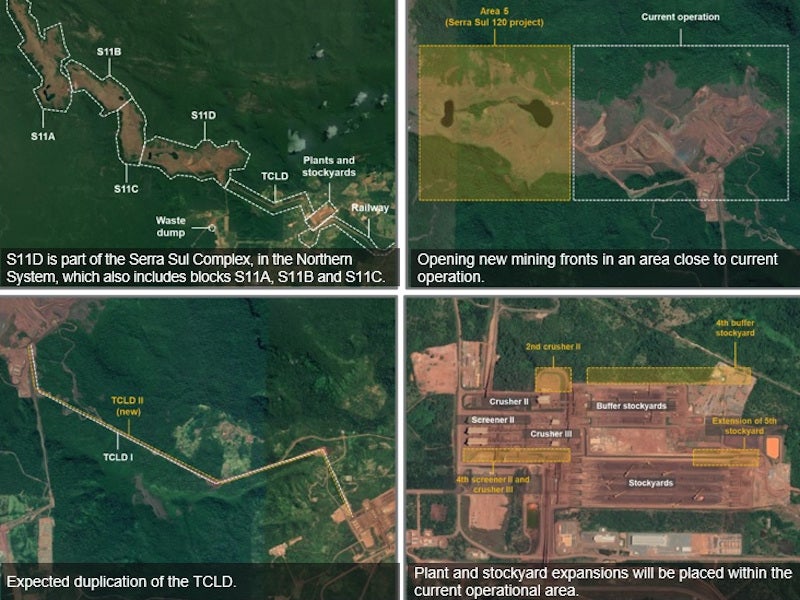

The Serra Sul 120 expansion project for the S11D mine-plant includes the exploration and opening of new mining areas, the establishment of new processing lines, duplication of long-distance belt conveyor (TCLD), and expansion of storage areas.

The expansion project will increase the total iron ore output of Vale’s Northern System from 240Mtpa to 260Mtpa.

Location and geology

The Serra Sul mine is located within Vale’s Northern System mining complex in Canaã dos Carajás, approximately 1,940km north of Sao Paulo in the Para state of Brazil.

Precambrian rocks of the Itacaiunas Supergroup host the iron deposits of the Northern Iron System.

Pium complex, ortho-granulites, and Cingu complex gneiss and migmatites form the basement of the region.

The Carajas formation have interbredded mafic meta-volcanics with mixed meta-sediments like fine grained tuffs, tuffaceous siltstones, phyllites, cherts and greywacke.

Iron ore reserves at Serra Sul

The S11C and S11D deposits of the Serra Sul mine were estimated to hold 4.19 billion tonnes of proven and probable reserves grading 66.7% Fe, as of December 2019.

Mining and ore processing

Ore is strip-mined at the S11D site using truck-less system. Excavators and movable crushers are used instead of trucks to extract iron ore and feed 30km of interconnected conveyor belts for the transportation of ore to the processing plant.

The ore is processed under natural humidity conditions at the plant without the use of water.

The processed ore material from the plan is transported in the 101km-long Carajas Railroad system (EFC) to the Ponta da Madeira Maritime Terminal (TMPM) in Sao Luis for shipping.

Infrastructure facilities

The S11D project site has eight operational buildings, which were constructed using modular design technique. The buildings were formed with 109 modules that were built at the nearby assembly park.

The mine is equipped with simulators to train operators for loading railroad cars with iron ore. It also uses drone technology for conducting aerial surveys for mine, plant, and ore piles.

The mine also features automation and control system for efficient management of energy resources. The natural moisture processing facility is installed at the site to reduce water consumption by 93%.

Contractors involved

A consortium of SNC-Lavalin and Worley Parsons was awarded the contract for the implementation of the S11D project in June 2010.

SNC-Lavalin’s scope of works included engineering services for the infrastructure and overland conveying facilities, civil works, electromechanical assembly, procurement support, construction management and providing key project management.

Worley Parsons was responsible for services related to the construction of modular ore processing facilities, as well as collaboration on procurement, construction and project management support.

ABB was contracted for the supply and installation of automation and electrical equipment for the ore separation process, as well as for a 230kV in-feed substation.