SOCAR Turkey Aegean Refinery (STAR) is an oil refinery located in Aliaga, Izmir Province, Turkey. Operated by STAR Rafineri, the facility has a processing capacity of ten million tonnes (Mt) of crude oil a year, which is equivalent to 214,000 barrels a day.

The refinery is jointly owned by the State Oil Company of Azerbaijan Republic (SOCAR, 60%) and the Ministry of Economy of Azerbaijan (40%).

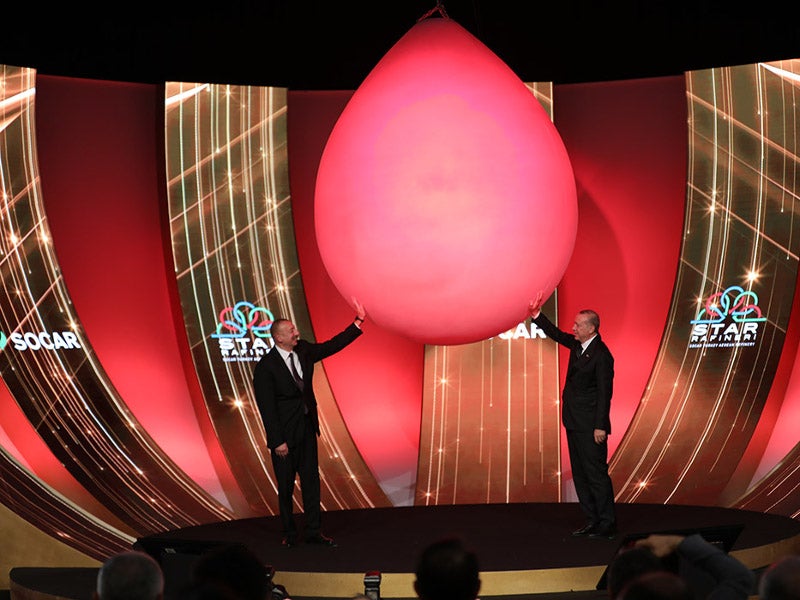

Developed with an estimated investment of £5bn ($6.3bn), the STAR oil refinery is one of the biggest investment projects in Turkey.

The oil refinery construction was started in October 2011 and operations were started in October 2018.

STAR Aegean refinery details

Located in the Petkim Aliaga complex area, Turkey, the STAR Aegean refinery is a high-complexity high-conversion oil refinery that processes natural gas and refinery fuel gas.

It includes a crude distillation plant with a capacity of 34,023 cubic metres a day (m³/d), a vacuum distillation plant of 13,514m³/d, a 6,067tpd saturated gas plant, and a 703tpd unsaturated gas plant.

A naphtha hydrotreater unit, a kerosene hydrotreater unit, and one diesel hydrotreater unit with capacities of 3,180m³/day, 4,134m³/day, and 10,811m³/day respectively are also installed at the refinery.

The facility also contains a hydrocracker unit (10,493m³/day), a delayed coker unit (6,380m³/day). and a continuous catalytic reforming (CCR) unit with a capacity of 4,452m³/day.

In addition, the refinery features a hydrogen generation unit with a capacity of 3.84 million normal cubic metres per day, a 1,317m³/day saturated liquefied petroleum gas (LPG) Merox unit, and a 422m³/day unsaturated LPG Merox unit.

It also has two sulphur recovery units and a tail gas treatment unit with a capacity of 487tpd of sulphur.

STAR Aegean refinery infrastructure

The STAR Aegean refinery is installed with 63 storage tanks with a combined capacity of approximately 1,640Mt. It features a marine terminal to enable the import of crude oil and export of refined products from the plant. The terminal includes four jetties with double berthing facilities for tankers.

The refinery also includes a waste water treatment unit.

STAR refinery products

The STAR refinery is designed to refine Azeri light, Kerkuk. and URALS oil to produce 4.8Mt of ultra-low sulphur diesel fuel, 1.63Mt of Jet fuel, and 320,000t of LPG a year.

It also produces petrochemical raw materials including 1.61Mt of naphtha and 422,000t of mixed Xylene a year.

Other refined products from the plant include 485,000t of reformates, 692,000t of petroleum coke, and 153,000t of sulphur a year.

The naphtha, LPG, and mixed xylenes produced by the refinery are sent to the Petkim petrochemical plant located adjacent to the refinery.

Financing for STAR refinery

An equity loan agreement for a sum of $3.29bn was signed between STAR Rafineri and 23 banks in June 2014.

The financing was provided by five exim banks including the Export-Import Bank of the United States, Japan Bank for International Cooperation, Korea Trade Insurance Corporation, Compañía Española de Seguros de Crédito a la Exportación, and Servizi Assicurativi del Commercio.

State Oil Fund of the Republic of Azerbaijan provided a financing of $1.3bn for the project.

Japan Bank for International Cooperation and Nippon Export and Investment Insurance signed a facility agreement with STAR Rafineri for providing a direct loan of $291m. The loan was co-financed by The Bank of Tokyo-Mitsubishi and several other Japanese banks.

Contractors involved

STAR Rafineri awarded the engineering, procurement, and construction contract for the refinery to a consortium of four companies including Tecnicas Reunidas, KS Engineering, Saipem, and ITOCHU.

The front-end engineering and design (FEED) contract for the refinery was awarded to Foster Wheeler and Fluor Consultants.

Axens provided the hydrotreater units, while FWI provided the crude distillation plant, a vacuum distillation plant, a saturated gas plant, and an unsaturated gas plant.

Honeywell (formerly UPO) was appointed as the main automation supplier for the oil refinery. It also provided a hydrocracker unit, a CCR Reformer unit, a saturated LPG Merox unit, and an unsaturated LPG Merox unit for the plant.

FW USA provided the delayed coker unit, while Technip Benelux provided the hydrogen generation unit and Technimont supplied two sulphur recovery units and tail gas treatment units.

ABB was responsible for providing the transmission and distribution substation, along with other electrical infrastructures for the project, under a contract awarded in March 2016.

Tekfen Construction and Installation Company, Temelsu, Keller Grundbau, and Samm Technology are some of the other contractors involved in the project.