Talcher power plant is a coal-fired thermal station located in Talcher within Angul district of Odisha, India. Operated by National Thermal Power Corporation (NTPC), the power station has an installed capacity of 460MW and will undergo a third stage expansion to add 1,320MW capacity.

The power station was owned by Orrisa State Electricity Board (OSEB), until it was acquired by NTPC in 1995.

NTPC approved an investment of Rs97.85bn ($1.34bn) for the expansion of the Talcher power plant in September 2018. The first 660MW unit of the stage three expansion is expected to be commissioned in 2022, followed by the second unit in 2026.

Talcher power plant make-up and expansion details

The first and second stages of the Talcher power plant have an installed capacity of 240MW and 220MW respectively, while the 1,320MW stage three expansion will bring the total capacity to 1,780MW.

The stage one of the plant includes four 60MW units commissioned respectively in December 1967, March 1968, July 1968 and 1969. Commissioned in March 1983, the stage two has two units with an installed capacity of 110MW each.

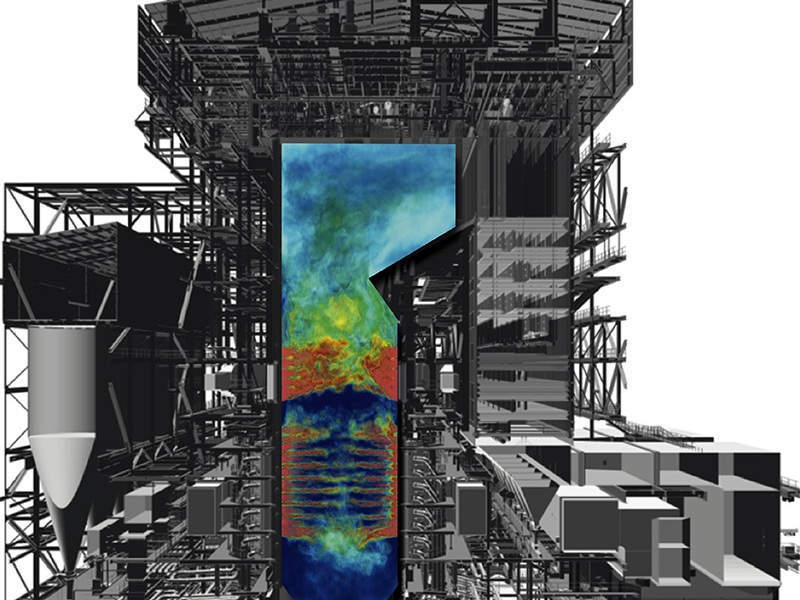

The proposed stage three will involve the installation of two pulverised coal-fired units of 660MW each. The units will feature ultra-super critical (USC) boilers, and single reheat steam generators with dry bottom type furnaces.

The steam generator will be suitable for outdoor installation, while the main steam flow at the superheater outlet will be 2,120 tons per hour (t/h). The air and flue gas system will contain two axial type forced draft and two induced draft fans as well as two pairs of regenerative rotary type air pre-heaters.

Other components of the brownfield project will include associated buildings, coal storage area, fly ash silos, ash slurry disposal system and light diesel oil (LDO) tanks for initial start-up, pump house, water treatment plant, cooling tower and cooling water pump house.

Details of the coal handling system of Talcher power plant

The coal required for the stage three units is estimated to be 6.9Mtpa, which will be sourced from Mahanadi coal fields located in Talcher area.

A new 2,200Mtph coal handling system with parallel double stream belt conveyors will be installed to handle the coal requirements of the plant. The system will have facilities for receiving, unloading, crushing and conveying the crushed coal to boiler bunkers and stacking the coal from crushed coal stockyards.

The coal transported by railway through BOBR wagons will be unloaded at the track hopper terminal. The stockyards will have a storage capacity equivalent to eight days of coal consumption of the two units.

Infrastructure

The power plant is well connected to major locations by rail as it is located approximately 2km away from the Talcher railway station on Talcher-Cuttack section of North Eastern Railway.

The plant is also served by Talcher Thermal, a small railway station located near the boundaries of the project site. It can also be accessed by two main highways NH-23 and NH-200.

The water required for the units to be added in the third stage will be sourced from River Brahmani. The Water Resource Department under the Government of Odisha allocated 52.8 cusecs of water from the upstream of Samal Barrage discharge on the River Brahmani.

A sewage treatment plant will be installed to treat the sewage from the plant, in accordance with the prescribed standards. The effluents will be utilised for plantation and horticulture.

An effluent treatment plant will be built to treat the effluents generated by the new units.