Thompson Creek project includes a primary, surface molybdenum mine and mill in the US state of Idaho.

The molybdenum project, along with Langeloth metallurgical facility near Pittsburgh, Pennsylvania, forms part of Canadian mining company Centerra Gold’s Molybdenum Business Unit (MBU).

Thompson Creek has been in care and maintenance since December 2014.

In September 2024, Centerra decided to restart operations at the mine. Restarting operations will entail an initial capital investment of around $397m.

The molybdenum mine is expected to commence operations in the second half of 2027 and supply high-grade feed to Langeloth.

Centerra expects its US Moly business to generate sustainable annual cash flows once Thompson Creek achieves full operation and is vertically integrated with Langeloth.

It is estimated that the combined business would produce an after-tax net present value (8%) (NPV 8%) of $472m.

Thompson Creek Mine Location

The Thompson Creek open pit molybdenum mine and concentrator is located in central Idaho, the US. The location is around 48km southwest of the town of Challis in Idaho’s Custer County.

Existing infrastructure at the location includes a processing facility, and waste and tailings storage facilities, mobile equipment fleet, access roads and offices among others.

The project has around 35 square miles of land, or about 22,500 acres under control which includes patented lode claims, placer claims, and mill site claims.

Ownership and Development History

The Thompson Creek deposit was discovered in 1968 by Cyprus Minerals Corporation.

Following an exploration campaign, Cyprus started construction work at the mine in 1981. The mine first commenced operations in 1983 with open pit mining.

Mining operations at the site continued in multiple phases. The seventh phase of mining ended in 2014, following which the molybdenum mine was placed on care and maintenance.

The project produced 180 million pounds of molybdenum from 89.6 million tonnes of ore at an average grade of 0.112% Mo between 2005 and 2014. During this period, mill recovery averaged 89.6%.

Meanwhile, Cyprus merged with Amax in 1993. A newly formed company Thompson Creek Metals Company acquired the deposit and operations, and recommenced operations in April 1994.

In 2006, Blue Pearl Mining acquired Thompson Creek Metals Company. A year later, the company changed its name to Thompson Creek Metals Company.

In 2016, Centerra Gold acquired all of the issued and outstanding common shares of Thompson Creek.

The new owner submitted a Modified Mining Plan of Operations (MMPO) in 2023 to include additional acreage for the pit highwall layback.

Centerra obtained mine permit authorisations for additional lands following environmental studies and regulatory reviews. The company holds all necessary permits and authorisation to advance with the Phase VIII Mine Plan.

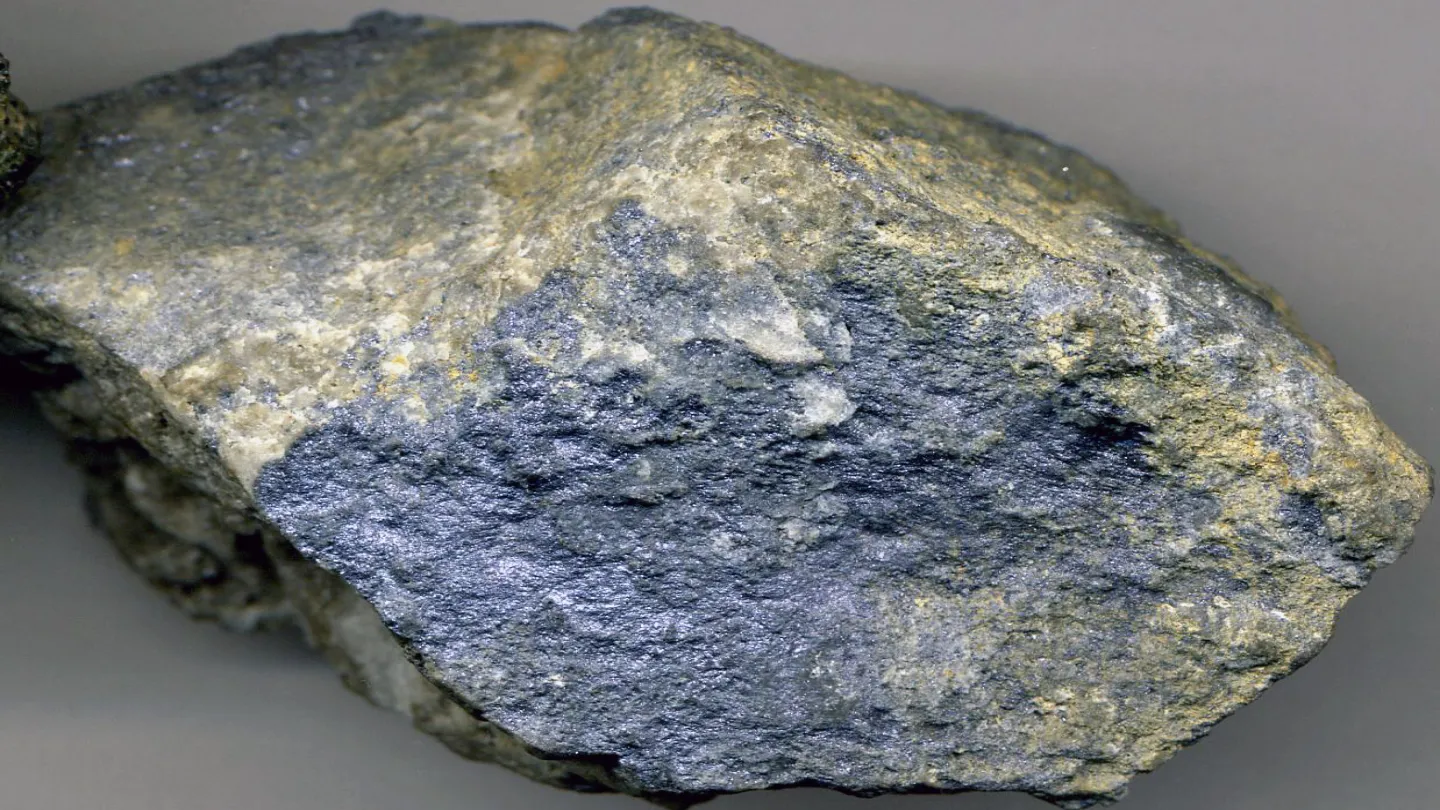

Geology and Mineralisation

At Thompson Creek, porphyry molybdenum deposit is found near the suture of the late Cretaceous Idaho Batholith in the west and complexly folded Paleozoic metasedimentary rocks in the east.

Molybdenite mineralisation is primarily hosted in the Thompson Creek intrusive complex, which is made of a granodiorite-quartz monzonite stock of Cretaceous age.

Within the intrusive rocks, alterations such as pyrite, quartz, and sericite were observed. This style, primarily found in veins at shallow depths, has been mostly mined out.

The dominant alteration at depth includes coarse biotite with some molybdenite found in quartz veins.

Mineralisation is largely limited to the granodiorite/quartz monzonite intrusion. The structure is generally elliptical.

The molybdenum mineralisation is found as crosscutting quartz-molybdenite-pyrite veinlet series, stringer zones, and rare coarse disseminations. The dominant vein runs parallel to the long dimension of the intrusive body.

The deposit at Thompson Creek is categorised as arc-related (Endako-type) porphyry molybdenum deposit.

Thompson Creek Mine Reserves

According to the results of the Thompson Creek feasibility study, the project is estimated to contain 125 Million short tonnes (Mst) of ore (Proven and Probable) at a grading of 0.065%. Contained in situ Molybdenum (Mo) metal is estimated to be 161 million pounds (Mlb).

Measured and indicated molybdenum resources are estimated to be 63 million pounds and inferred molybdenum resources to be 17 million pounds.

Mining at Thompson Creek

The Thompson Creek Mine operated as a conventional hard rock open pit mine self-performing all drill, blast, load, haul, and support activity.

The project is expected to continue self-perform major mining activities in the future. It is expected to process mineralised ore from the same deposit, as metallurgical testwork confirmed molybdenum recovery with historical operations.

Mining will involve using two existing cable shovels, a Bucyrus 495HD and a P&H 2300, as the primary loading units. Existing Cat 789C haul trucks will be reconditioned, and two other haul trucks to support operations.

A new Atlas Copco Pit Viper 271 and two existing drills will be used for blast-hole drilling.

Centerra plans to mine ore at an average rate of 35,000 tons per day, most of which will be transferred to the primary crusher to maintain the 28,500 st/d plant throughput rate.

Waste rock will be disposed into the Buckskin waste rock storage facility (WRSF) or the Pat Hughes WRSF.

Mining will begin in the South phase with mill feed to begin processing in the fourth year. The project is expected to reach full capacity in the fifth year.

Recovery and Ore Processing

Thompson Creek Mine Project will leverage existing process plant facilities to treat ore.

Run of mine (ROM) ore will be transported to the primary gyratory crusher via haul trucks. After crushing, the ore product will be passed to the coarse ore stockpile via a series of two overland conveyors.

There will be two process lines to reclaim stockpiled ore into dedicated conveyors and SAG mills. The overland conveyors and SAG mill feed conveyors will undergo maintenance before restarting operations.

The two grinding lines, with a combined capacity of 1,290 st/h, will be revamped before restarting operations.

As part of an upgrade, the facility will be equipped with a cyclone pump-box, a particle size analyser, and a new liner and lifter design for the SAG mills.

Further, two new banks of rougher flotation cells will be installed to support molybdenum recovery of around 94%.

Rougher tailings will be passed through the pyrite removal flotation circuit before delivery to the TSF. The concentrate will be further processed for additional molybdenum recovery.

The resultant concentrate will be then screened, thickened, and delivered to the concentrate leaching process.

The leaching process will separate impurities such as copper and lead to enhance the grade and quality of the molybdenum concentrate.

Subsequently, the leached molybdenum concentrate will be dewatered using filter presses.

A Holoflite dryer will be used to reduce moisture in the filtered molybdenum concentrate cake before packaging.

Contractors Involved

The Thompson Creek feasibility study was prepared by qualified personnel from Centerra, mining consultant Call & Nicholas, engineering firm AtkinsRéalis, Hatch, Lorax Environmental Services and consulting firm WSP USA.