The 22.5GW Three Gorges Dam hydropower station is the world’s biggest hydroelectric power project.

Located on China’s longest river Yangtze, approximately 44km from the city of Yichang in Hubei province, the hydroelectric facility generated its first power in July 2003 and achieved its full operating capacity after the last of its 32 turbine generators was commissioned in July 2012.

Construction on the CNY207.27bn ($29bn) giant hydropower project started in 1994. State-owned China Three Gorges Corporation (CTG) is the developer and operator of the project.

The Three Gorges Dam power station generated 38.9 billion kWh of electricity in the first half of 2018, with which the cumulative power generation of the plant since it was brought into operation reached 1.13 trillion kWh.

Project Gallery

-

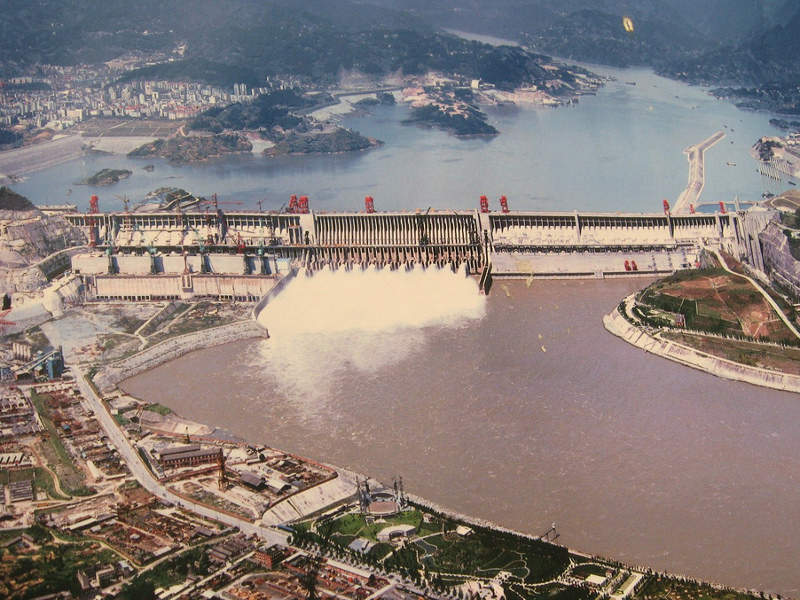

At 22,500MW installed capacity, Three Gorges Dam is the world’s biggest hydroelectric power facility. Image courtesy of Pedro Vásquez Colmenares.

-

Three Gorges Dam hydroelectric power plant is built on Yangtze River, the longest river in China. Image courtesy of Andrew Clarke.

-

Three Gorges Dam power plant has been operational since 2003. Image courtesy of Marshall Segal.

-

Three Gorges Dam hydroelectric power plant is equipped with 32 Francis turbines of 700MW capacity each. Image courtesy of John.U.

Three Gorges Dam history and development phases

Although detailed planning for the Three Gorges Dam started in 1955, the project could not take off the ground for approximately 40 years due to the perceived danger of dam collapse and massive displacement risks.

The National People’s Congress finally ratified the decision to build the dam in 1992 based on a feasibility study completed in 1988 and construction of the dam officially began in 1994.

The project was developed in four phases following the preparatory phase. The first phase, completed in 1997, involved earthworks for the development of basic structure for the power facility as well as the diversion of the Yangtze River.

Construction of the main wall of the dam was completed in 2006, making Three Gorges the world’s biggest dam structure at that time. It involved the excavation of 102.83 million m³ of stone and earth, 31.98 million m³ of stone and earth refilling, and 27.94 million m³ of concrete placement.

The second phase involved the installation of 14 Francis turbine generator units of 700MW capacity each on the left bank of the river. Main equipment supply contracts for the 9,800MW initial capacity were awarded in 1997. The first 14 units of the plant were brought into operation between 2003 and 2006.

The dam height was also increased to 87m and a 135m-high, permanent ship-lock was built on the southern bank, during the second phase.

During the third phase, the dam was raised to its maximum height of 185m and 12 additional Francis turbine generator units of 700MW capacity each were equipped on the northern bank of the river, increasing the total installed capacity of the plant to 18,200MW by October 2008.

The final development phase of the project involved the installation of six 700MW Francis turbine units in the underground power house of the plant in 2011 and 2012, which along with two 50MW plant power generators increased the total installed capacity further to 22.5GW.

Three Gorges Dam power plant make-up

The 22.5GW Three Gorges Dam power complex comprises a 185m-tall and 2.3km-long concrete gravity dam on the Yangtze River, two dam-toe power houses on the left and right banks of the river, an underground power house, and a power source station.

The dam creates the 667km-long Three Gorges reservoir with an average width of 1.57km, surface area of 1,045km² and storage capacity of 45 billion m³.

The left bank power house is equipped with 14 Francis turbine generator units of 700MW capacity each, whereas the right bank power house is fitted with 12 similar generating units. The underground house is installed with six 700MW turbine generator units. The power station also utilises two small 50MW hydro-turbine generating units.

The hydropower station utilises the designed total water head of 113m.

The water inlet steel pipes connecting the turbine are of 12.4m diameter, whereas the power shafts linking the turbines and the generators are 3.8m in diameter.

Power transmission from Three Gorges

The power generated by the plant is transmitted through the Three Gorges Project (TGP) power transmission and transformation network to the Central China, Eastern China, Southern China and Sichuan-Chongqing Power Grid.

Power is evacuated as 20kV Alternating Current (AC) and transmitted to a booster station for conversion into 500kV AC.

Electricity to Central China Power Grid and Sichuan-Chongqing Power Grid is directly transmitted through 500kV AC transmission lines, whereas that for Eastern China Power Grid and Southern China Power Grid is first sent to a convertor station for conversion into 500kV direct current (DC) before being transmitted through long-distance DC transmission lines.

The project utilises 16 AC/DC transmission circuits, with the longest transmission line being 1,300km-long.

The TGP power transmission and transformation infrastructure was completed in December 2007 at a cost of approximately CNY34.3bn ($5bn).

Financing for Three Gorges Dam project

The Three Gorges Dam project is estimated to have cost up to CNY207.27bn ($29bn), which was financed mainly through TGP construction fund, China Development Bank (CDB) loan, Three Gorges bonds and export credit facilities.

Major contractors involved with the Three Georges Dam project

Canadian International Project Managers Yangtze Joint Venture (CYJV) a consortium led by Canadian International Project Managers (CIPM) and including Acres International, BC Hydro, SNC and Lavalin, carried out the feasibility study for the project for China’s Ministry of Water Resources and Electric Power between 1985 and 1988.

The $15m feasibility study was sponsored by the Canadian International Development Agency (CIDA).

Bechtel Enterprises provided consulting services to the Three Gorges project in the 1980s.

Turbines and generators for the first 14 generating units of the plant were supplied by two groups of foreign companies, with Alstom-ABB-Kvaerner being responsible for eight units and Voith- Siemens-GE providing the remaining six units.

Turbine and electrical contractors for Three Gorges Dam

The subsequent turbine generator sets for the project were constructed and installed by Chinese companies such as Harbin Power Equipment, Dongfang Electrical Machinery, China Gezhouba Group Mechanical and Electrical Construction, through technological transfer.

ABB was awarded contracts worth $1.3bn between 1999 and 2004 for the supply of transformers, gas-insulated switchgears, automation controls systems, and three high-voltage direct current (HVDC) links for the Three Gorges project.

Nanjing Goulds Pump, a Chinese subsidiary of TT Industries was contracted in 2000 to provide 48 deep-well pumps for the five permanent ship locks for the Three Gorges facility.

AGRA Monenco, a subsidiary of AGRA Industries provided project management technology including systems engineering, system layout, equipment installation, testing, system operation guidance software, and user training for the project between 1995 and 1999.

Teshmont Consultants was engaged for the first direct current high-voltage transmission line study and design for the Three Gorges dam project. The company also provided engineering consulting services for high-voltage electrical equipment of the left bank power house.

ABB supplied electrical equipment for the right bank power plant as well as 12 sets of three-phase 840MVA/550KV power transformers, two converter stations and high-voltage switchgear equipment to an electrical substation for the Three Gorges project.

Construction contractors

Harza Engineering was contracted to supervise the construction of the Three Gorges dam in 1999.

Dominion Bridge was contracted to build a $64m cement plant for the construction of the Three Gorges dam, while Cifa and CS Johnson were contracted for supplying two of four major concrete batching plants for the project.

Potain, a member of Paris-based Legris Industries Group, supplied two large cranes for the project.

The other major construction equipment suppliers for the project included Baur, Krupp Fördertechnik, Mannesmann Demag, Mitsubishi, NKK Corporation, Terex Equipment, Rotec Industries and Fuchunjiang Hydropower Equipment Works.

Atkinson Construction was contracted in 1999 to provide consulting services for the installation, operation, maintenance, and management of imported large equipment used during the dam construction.

The major Chinese construction contractors involved in the project were Gezhouba Share Holding, Yichang Qingyun Hydropower Joint Management and Yichang Three Gorges Project Construction 378 Joint Management.

Displacement and resettlement for Three Gorges Dam project

The Three Gorges Dam project caused displacement and resettlement of 1.3 million people between 1993 and 2009, which is considered to be the biggest population resettlement for a hydropower project in human history.

The total submerged land area for the project was more than 632km², which included 13 cities, 140 towns and 1,350 villages.

The massive hydroelectric project also caused relocation of 1,632 industrial and mining enterprises.