Tres Estradas phosphate project is an open-pit mine located in Rio Grande do Sul, Brazil. Aguia Resources fully owns the project and is developing it with an estimated capital expenditure of $75.6m (£60.2m).

Bankable feasibility study (BFS) of the project was completed in March 2018, while the grant of Preliminary License (PL) is awaited.

The project is designed to be developed in three phases, which will produce saprolite and carbonatite during the first 16years of mine life. In addition, the project will produce aglime for a period of 20 years.

The three-stage phosphate mine is anticipated to produce 300,000 tonnes per annum (tpa) of phosrock concentrate in the first stage. The second stage will involve the production of one million tonne per annum (Mtpa) of aglime in addition to phosrock concentrate.

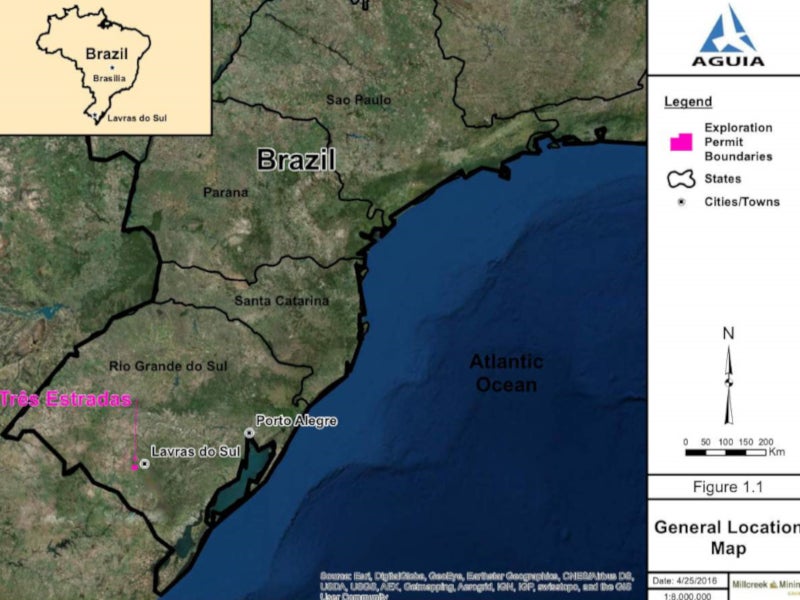

Tres Estradas phosphate project location and geology

The phosphate project is situated approximately 320km from Porto Alegre, Rio Grande do Sul, Brazil.

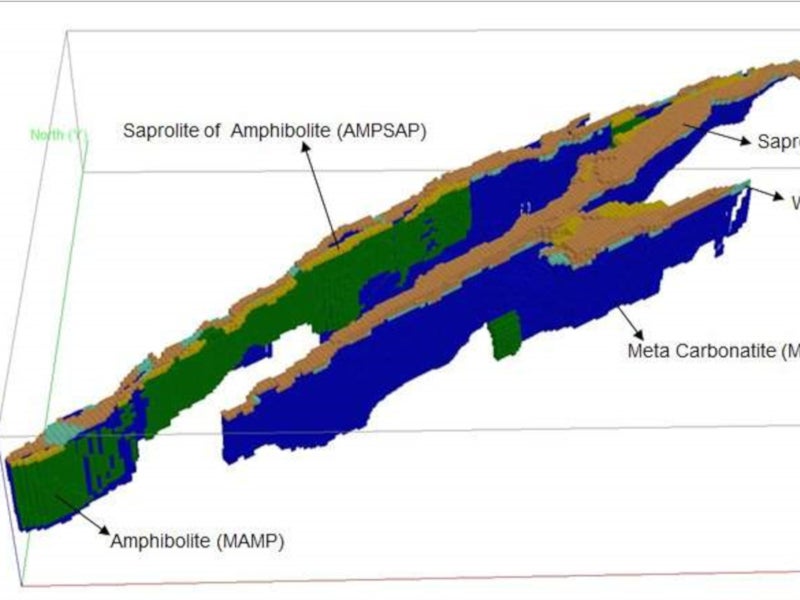

The site is located on the in the Santa Maria Chico Granulitic Complex (SMCGC), which is a part of the Taquarembo domain. The granulite complex is surrounded by Ibare Lineament on the north-east side, Phanerozoic cover on the west, and by Neoproterozoic Braziliano granites on the south.

Tres Estradas deposit consists of a stretched meta-carbonatite and amphibolite intrusion, which forms a tightly folded sequence. The surface of the intrusion is approximately 2.5km-long and 300m-wide and is bound by biotite gneiss and meta-syenite along its north-east and south-east boundaries.

Phosphate mineralisation at the project occurs as mineral apatite, which is the sole phosphate-bearing mineral occurring in the carbonatites. It hosts phosphate mineralisation in fresh and weathered meta-carbonatite and amphibolite.

The Tres Estradas phosphate project is designed to be developed in three phases

Tres Estradas phosphate project reserves

The proven and probable ore reserves at the Tres Estradas phosphate mine are estimated to be 43.6Mt grading 4.31% phosphorus pentoxide.

Mining at Tres Estradas phosphate project

Conventional open-pit, truck and shovel mining methods will be used at the Tres Estradas phosphate project. The project is estimated to recover 43.5 million tonnes (Mt) of run-of-mine (ROM) ore.

Phase one will involve the mining of high-grade oxidised ore, followed by the extraction of fresh and low-grade carbonatite in the second phase. The processing plant will be expanded as part of the second phase to produce carbonatite. The third phase will focus on the production of aglime alone.

The mining fleet planned to be used includes CAT 374F hydraulic excavator, two CAT 99 2K front-end loaders, six Scania G440 transport trucks, and nine CAT 775G end dump trucks.

Processing at Tres Estradas phosphate project

The run-of-mine (RoM) ore will be transported to the 1.3Mtpa processing plant, where it will be fed into the toothed roll crusher via an apron feeder. The first phase will treat the saprolite ore , with the concentration plant producing approximately 300,000tpa (dry-basis) of phosphate concentrate.

The ore will be crushed in a primary crushing circuit and stockpiled before being conveyed to a grinding circuit. The resultant product will undergo phosphate processing in a column flotation circuit consisting of a rougher and cleaner cells, magnetic separation utilising high-intensity magnetic separation (HIMS).

The concentrate will be thickened and dewatered using pressure filters, dried, and transferred to truck loadout.

The processing plant will be added with a new primary crushing circuit, grinding mills, flotation columns, and aglime dewatering facilities as part of the second phase.

The ore will pass through a primary jaw crusher and a secondary cone crushing circuit followed by two-stage open grinding circuit. The second phase will apply the same processing method to produce a phosphate concentrate.

The underflow from the carbonatite tailings thickening stage will be transferred to aglime conditioning tank. Aglime will be either conveyed to the tailings storage dam or to the pressure filtration system for dewatering before sale.

The remaining tailings from the tailings storage dam facility are proposed to be reclaimed and depleted before dewatering. It will be then sold as an unprocessed aglime product.

Financing for the Brazilian phosphate project

Nebari has agreed to finance up to 100% of the capital expenditure required to develop the project, under a non-binding memorandum of understanding (MoU) signed in June 2017.

Infrastructure

The Tres Estradas project can be accessed by RS-357 highway from Lavras do Sul and then through the BR-473 highway.

The project is well connected to Porto Alegre, the capital city, and to the markets at the Rio Grande Port Hub.

Water for the project will be supplied by CORSAN, a state-owned water utility, while power supply will be sourced from the Bage substation, which is owned by Companhia Estadual de Energia (CEEE).

A railroad, operated by RUMO Logistics, traverses through the phosphate project area and through Lavras do Sul.

Contractors involved

Millcreek Mining Group was contracted to prepare NI 43-101 technical report for the BFS of Tres Estradas phosphate project.

ECM Engenharia and Walm Engenharia, two local consultant companies, supported Millcreek in the technical report preparation.

Millcreek was also supported by consulting firms such as Figener Engenheiros Associado, Agroconsult, Macrologística Consultoria, Azevedo Sette Advogados, L&M Assessoria Empresarial, Prominas, and Golder Associates.

SRK Consulting (Canada) prepared the Tres Estradas phosphate project’s preliminary economic assessment (PEA) report, which was later updated by Millcreek.