The Vulcan lithium project is a lithium brine extraction project proposed to be developed Vulcan Energy in the Upper Rhine Valley region in southern Germany. It is envisaged to be one of the world’s first lithium operations with a net zero carbon footprint.

The pre-feasibility study (PFS) for the project was published in January 2021 with the definitive feasibility study (DFS), piloting test works, permitting processes, and the advancement of off-take agreements planned to be pursued throughout the year.

The PFS is focused on lithium brine extraction at the Ortenau and Taro leases utilising on-site geothermal power generation.

The project is expected to produce up to 39,400 tonnes per annum (tpa) of battery-grade lithium hydroxide monohydrate (LHM) over an estimated operational life of 30 years. The total capital investment on the project is estimated to be approximately £1.54bn (€1.74bn).

The Vulcan project represents one of the biggest lithium deposits in Europe. Once in operation, it is expected to reduce Europe’s dependence on China for its lithium hydroxide supply.

Project location and geology

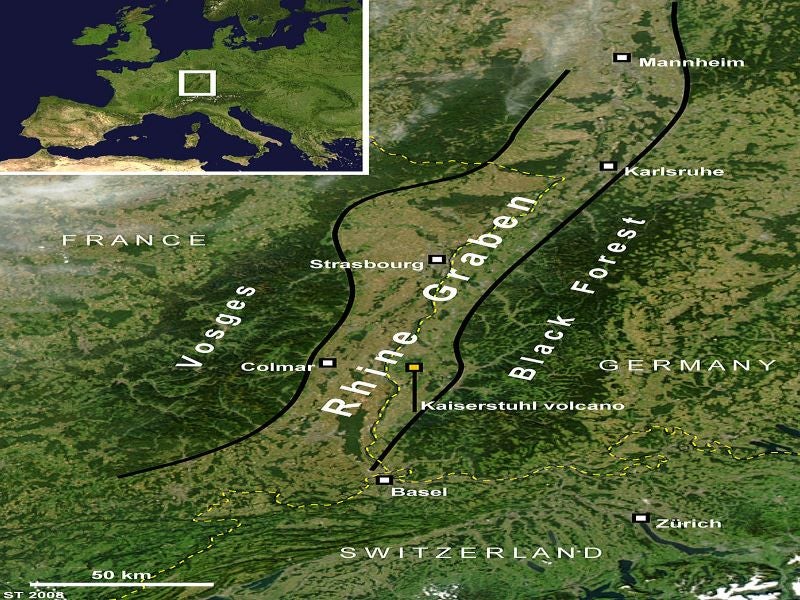

The Vulcan lithium project is located within the Upper Rhine Valley area in southwest Germany. Vulcan holds full ownership on licenses for Mannheim and Ortenau areas and an earn-in agreement with Global Geothermal Holding UG (GGH), which holds a granted license on Taro.

The geology of the Vulcan lithium property is characterised as a Cenozoic graben, composed of Permian to Tertiary sedimentary rocks with minor Tertiary volcanism and Quaternary surficial deposits.

The project is focused on aquifers associated with the Permo-Triassic strata, which is a collection of the Permo-Carboniferous Rotliegend Group sandstone and the Lower Triassic Buntsandstein Group sandstone.

Mineralisation and reserves

The lithium mineralisation at the Vulcan lithium project occurs in the brine within the Permo-Triassic aquifer pore space. The mineralization at Ortenau and Taro occur at depths of up to 4,004m in confined, subsurface aquifers of the Lower Triassic Buntsandstein Group sandstone within the Upper Rhine Graben (URG).

The indicated and inferred mineral resources at the Vulcan lithium project were estimated at to be 15.85 million tonnes (Mt) lithium carbonate equivalent (LCE) grading 181mg/l of lithium as of January 2021.

Brine extraction and lithium processing

The brine extraction operations will employ deep geothermal wells drilled to depths of up to 5km depending on the location to access the brine hosted in pore spaces of sediments and natural fault fractures. The brine will flow to the wells and will be pumped to the surface while developing cones of depression around the individual wells.

The project development proposal includes the construction of three geothermal power plants at the Ortenau site with three production wells dedicated for each power plant. The Taro area will feature two geothermal power plants with one plant having three production wells while the remaining two plants will have two production wells each. The total energy generation capacity from the geothermal plants is estimated to be 74MW.

Each well site will have a direct lithium extraction (DLE) plant to extract a lithium chloride solution from the brine at a recovery rate of 90%. The lithium chloride solution will then be sent to a central lithium plant (CLP) for the production of battery-grade lithium hydroxide monohydrate (LHM) at a rate of 39,400tpa.

The lithium chloride solution obtained from the DLE plants will undergo purification and electrolytic conversion for the production of lithium hydroxide (LiOH) solution, along with chlorine, and hydrogen gas. The LiOH solution will be further crystallised and purified to produce battery-grade LHM which will be bagged and made ready for shipping.

Contractors involved

Geo Thermal Engineering, a German-based engineering company, was engaged for the geology, hydrogeology and geothermal sub-surface studies for the PFS, while the mineral resource modelling and estimation were provided by APEX geosciences.

Gec-Co Global Engineering was engaged for the engineering studies pertaining to the geothermal power plants, while the process plant design and cost estimates were provided by Hatch.