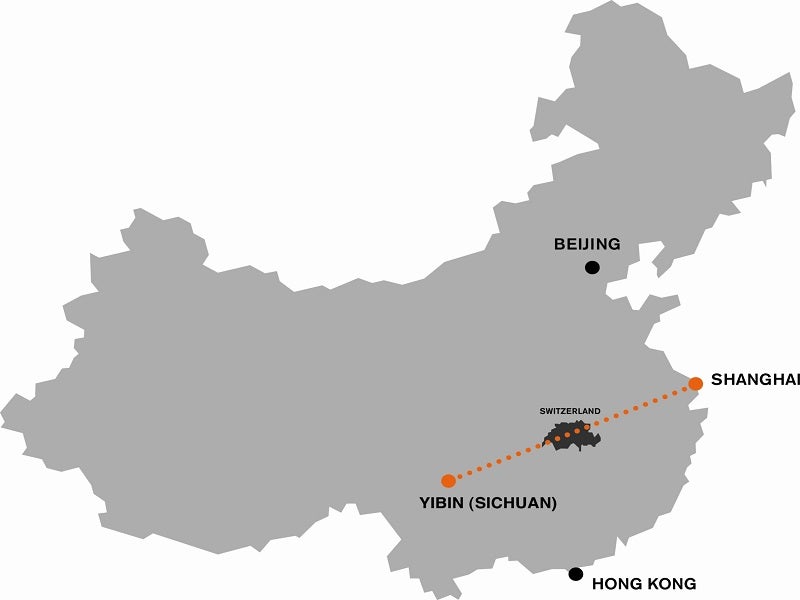

The Xiangjiaba-Shanghai ultrahigh voltage direct current (UHVDC) link is one of the longest transmission projects in the world with a length of 1,980km. The transmission line carries electricity generated by the Xiangjiaba hydroelectric power plant in the Sichuan province to Shanghai.

Developed by State Grid Corporation of China (SGCC), the UHVDC system has a voltage of 800kV and a capacity of 7.2GW. The project was approved in April 2007 and commissioned in July 2010. The electricity supplied by the transmission line is sufficient to meet the needs of 24 million people.

The UHVDC technology used by the transmission line enables direct current (DC) electricity to be transmitted at high voltages and at an efficient rate that prevents losses up to 0.7% of the rated power. The technology also helps in saving 1.2 million tonnes of carbon emissions from the project due to low energy wastage.

Xiangjiaba-Shanghai ultrahigh voltage direct current link details

The Xiangjiaba-Shanghai link was developed to transmit the electricity produced from the Xiangjiaba hydroelectric power plant situated on the Jinsha River in the Sichuan province to Shanghai, where electricity demand is booming.

The transmission line starts from the Fulong rectifier converter station in Yibin city, approximately 8km south of the Xiangjiaba power plant and ends at Fengxian substation in Shanghai. It passes through eight provinces including Sichuan, Chongqing, Hubei, Hunan, Anhui, Zhejiang, Jiangsu and Shanghai, while crossing over the Yangtze River four times.

The Fulong converter station is connected to the Xiangjiaba power plant by 12km-15km long 500kV alternate current (AC) lines, while the Fengxian substation is connected to the Nanhui substation in Shanghai through three 4km long 500kV AC lines.

Technology used in Xiangjiaba-Shanghai UHVDC system

Xiangjiaba-Shanghai uses single-phase, two-winding converter transformers, manufactured partly in China and Sweden. The converter bridges feature air-insulated water-cooled thyristor valves, which are arranged in double-valve configuration.

Each single valve in the Fengxian substation consists of 56 YST130 (6in) type thyristors. The thyristors have been specifically developed for high current applications.

The transmission line can transmit full rated power up to the specified maximum ambient temperature without the need for redundant cooling in service. A continuous overload of 105% and a two hour overload of 113% of rated power can be achieved with redundant cooling in service but with lower ambient temperature, the overload can be even higher.

Contractors involved

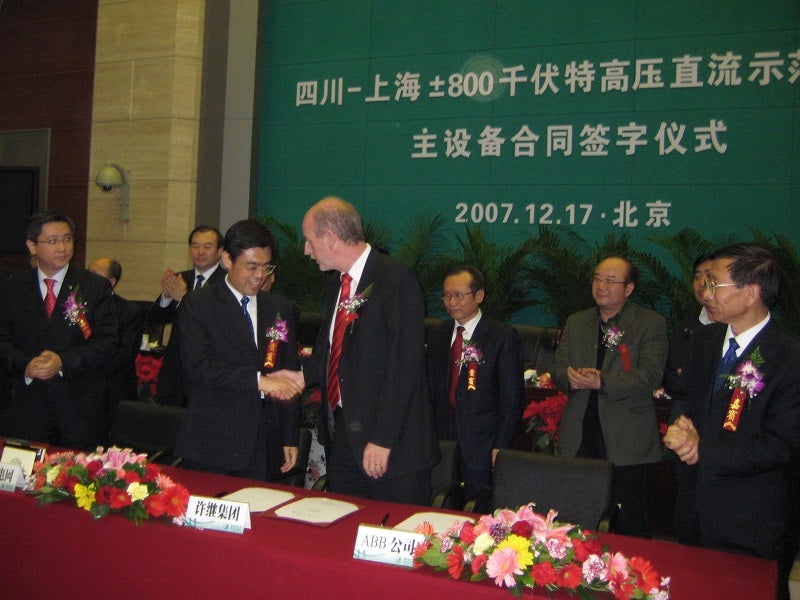

ABB was awarded a £283.3m ($440m) contract to design the overall system and supply 28 ultrahigh-voltage converter transformers. The company also supplied high voltage equipment such as thyristor valves, DC and AC switchyard equipment and the DCC800 HVDC control system.

GE was responsible for the design, testing and installation of a knee type disconnector featuring an equilateral triangle insulator support.

TBEA, a power transformers and electrical equipment company, researched and designed the transformer, wire, and cable used in the project.

Power China was responsible for the construction of the Fengxian converter station, while Shenzhen Tieon Energy Technology supplied power supply technology solutions for the Fulong substation.

Siemens supplied 6in thyristors, while Dalian Insulator Group supplied DC porcelain-suspension products for the transmission line.

Anhui Electric Power Design Institute performed surveys for one of the sections of the transmission line.

Xianjiaba hydroelectric power plant details

The Xiangjiaba hydroelectric power plant is one of four hydroelectric power plants developed on the Yangtze River. Three Gorges, Gezhouba, and Xiluodu are the other three power plants. Operated by China Yangtze Power, the power plants together have an installed capacity of more than 45GW.

The Xiangjiaba power plant was developed under the Jinsha river development project on the Jinsha River, which is one of the upper stretches of the Yangtze River.